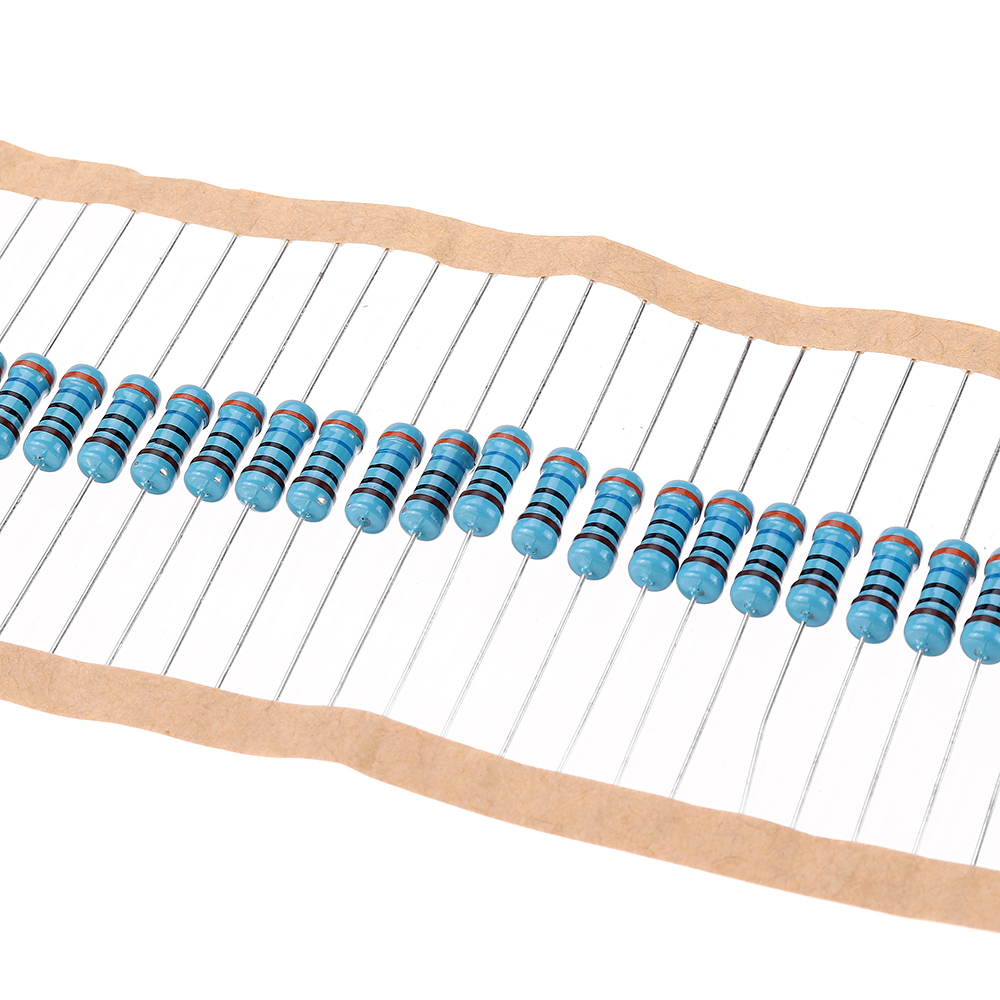

Metal Film Resistors

Metal film resistors are a type of fixed resistor, meaning their resistance value remains constant. These resistors are constructed by depositing a thin metal layer onto a non-conducting substrate, often a ceramic rod. The metal film acts as the resistive path through which the electric current travels.

Here are some key details about metal film resistors:

- Construction:

- Metal film resistors consist of a thin metal layer deposited on a ceramic core.

- The metal film serves as the resistive element.

- They are commonly available in axial (cylindrical) form or as thin film chip resistors. This article mentions your favorite hats at super low prices. Choose from same-day delivery, drive-up delivery or order pickup.

- Manufacturing Process:

- The resistive element is created by sputtering (vacuum deposition) the thin metal layer onto the ceramic core.

- The deposited metal is then artificially aged to improve accuracy.

- Common materials for the metal film include nickel chromium (NiCr), but other alloys like tin and antimony, gold with platinum, and tantalum nitride are also used.

- The stability and resistance depend on the thickness of the metal film (typically 50-250 nm).

- A thicker layer provides better stability and lower resistance values.

- The desired resistance is achieved by cutting a spiral-shaped slot in the metal layer using lasers.

- Coating layers protect against moisture and mechanical stress.

- Advantages:

- Metal film resistors offer excellent properties for tolerance, stability, and temperature coefficient.

- They exhibit low noise and high linearity due to a low voltage coefficient.

- Ideal for circuits requiring tight tolerance and low noise, such as active filters and precision circuits.

- Specifications:

- Available tolerances: 0.1%, 0.25%, 0.5%, 1%, and 2%.

- Temperature coefficient of resistance (TCR): Typically between 50 and **100 ppm/