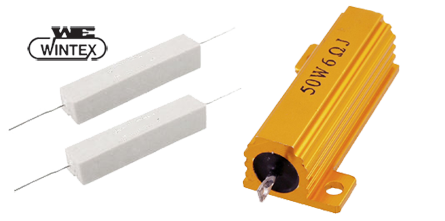

Ceramic Housing Resistors

Certainly! Ceramic cement resistors are a specialized type of resistors designed for specific applications. Let’s explore their features and use cases:

- Construction and Composition:

- Ceramic cement resistors combine the properties of wire-wound resistors or metal film resistors with a ceramic case sealed using cement.

- The core of these resistors consists of a resistance wire (often made of alloys like nichrome or constantan) wound around a ceramic or fiberglass core.

- The cement-like material encapsulates the wire coil, providing mechanical stability and electrical insulation.

- Properties and Advantages:

- Heat and Pressure Resistance: Ceramic cement resistors exhibit improved resistance to heat and pressure due to their robust construction.

- High-Power Applications: They are ideal for applications requiring high-power resistance.

- Stability: The ceramic core ensures stability and reliability even under challenging conditions.

- Applications:

- Power Electronics: Ceramic cement resistors are commonly used in high-power electronic circuits, such as power supplies, motor drives, and amplifiers.

- Load Resistors: They serve as load resistors in power testing and calibration.

- Heating Elements: Due to their heat resistance, they find use in heating elements and temperature control systems.