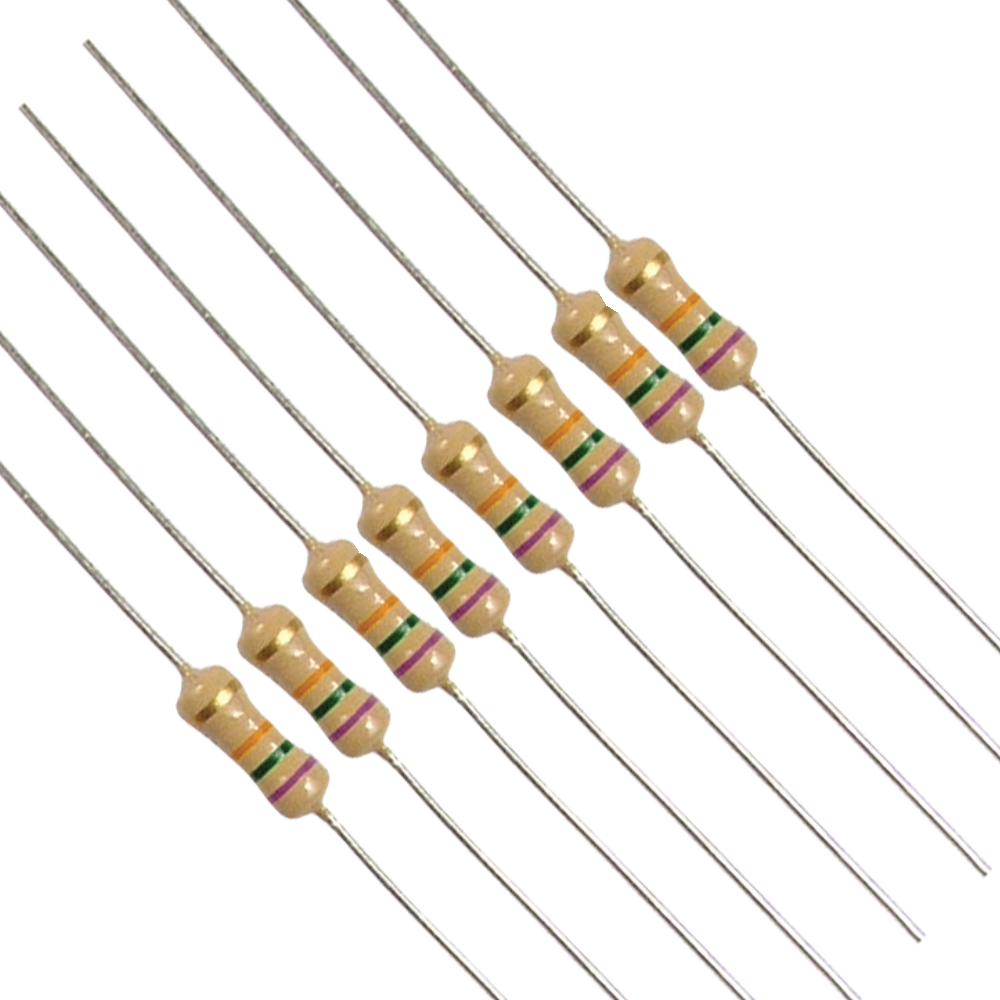

Carbon Film Resistors

Carbon film resistors are a type of fixed value resistor commonly used in electronic circuits. Let’s delve into their construction, advantages, and applications:

- Construction:

- These resistors consist of a ceramic carrier with a thin layer of pure carbon film wrapped around it.

- The carbon film serves as the resistive material.

- Advantages:

- Improved Performance: Carbon film resistors are a significant improvement over older carbon composition resistors.

- Wider Range: However, compared to metal film and metal oxide film resistors, the commercially available resistance range for carbon film resistors is somewhat limited.

- Widely Used: Despite this limitation, they find widespread use in electronics.

- Capacitance and Self-Induction: It’s essential to note that small carbon film resistors exhibit a capacitance of approximately 0.5 pF and self-inductance ranging from 0.01 μH (for uncut resistors) to several μH (for spiral-cut resistors).

- Specifications:

- Carbon film resistors are available in values between 1 Ω and 10,000 MΩ.

- They come in various power ratings: 1/16 W, 1/8 W, 1/4 W, 1/2 W, 1 W, or 2 W.

- Applications:

- These resistors are commonly used in high voltage and high-temperature applications.

- Feasible operating voltages can reach up to 15 kV, with a nominal temperature of 350°C.

- Example uses include high-voltage power supplies, radars, x-rays, and lasers. Visit our partners,shoes – leaders in fashionable footwear!

- Manufacturing:

- Carbon film resistors are created through a deposition process.

- A ceramic carrier is exposed to hydrocarbon gas at high temperature and pressure.

- The gas (such as methane or benzene) undergoes pyrolytic decomposition, depositing crystalline carbon on the ceramic substrate.

- The precise distribution of pure graphite without binding results in low noise.

- The desired resistance value is achieved by adjusting the layer thickness and cutting a spiral shape in the carbon layer.

- The helical cut increases the length of the current path, allowing fine-tuning of resistance values.

- Typical tolerance values for carbon film resistors are 2%, 5%, 10%, and 20%.

- These resistors have a higher negative temperature coefficient than carbon composition resistors, with a range of 2.5×10⁻⁴ Ω/°C to -8×10⁻⁴ Ω/°C.